Machines

We offer simple solutions for different manufacturing processes.

MACHINES

Our current machines

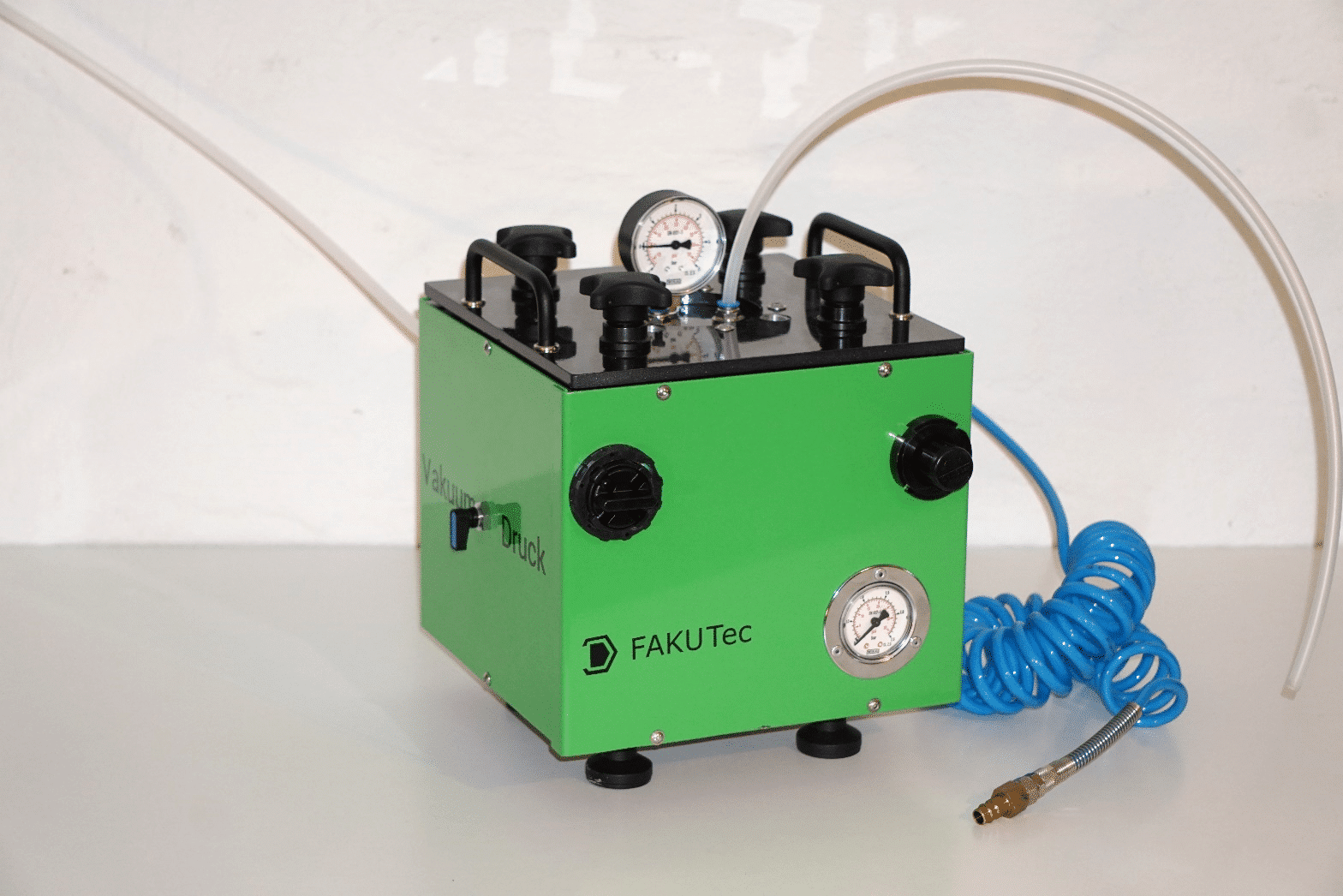

RTMBox

KLEBox

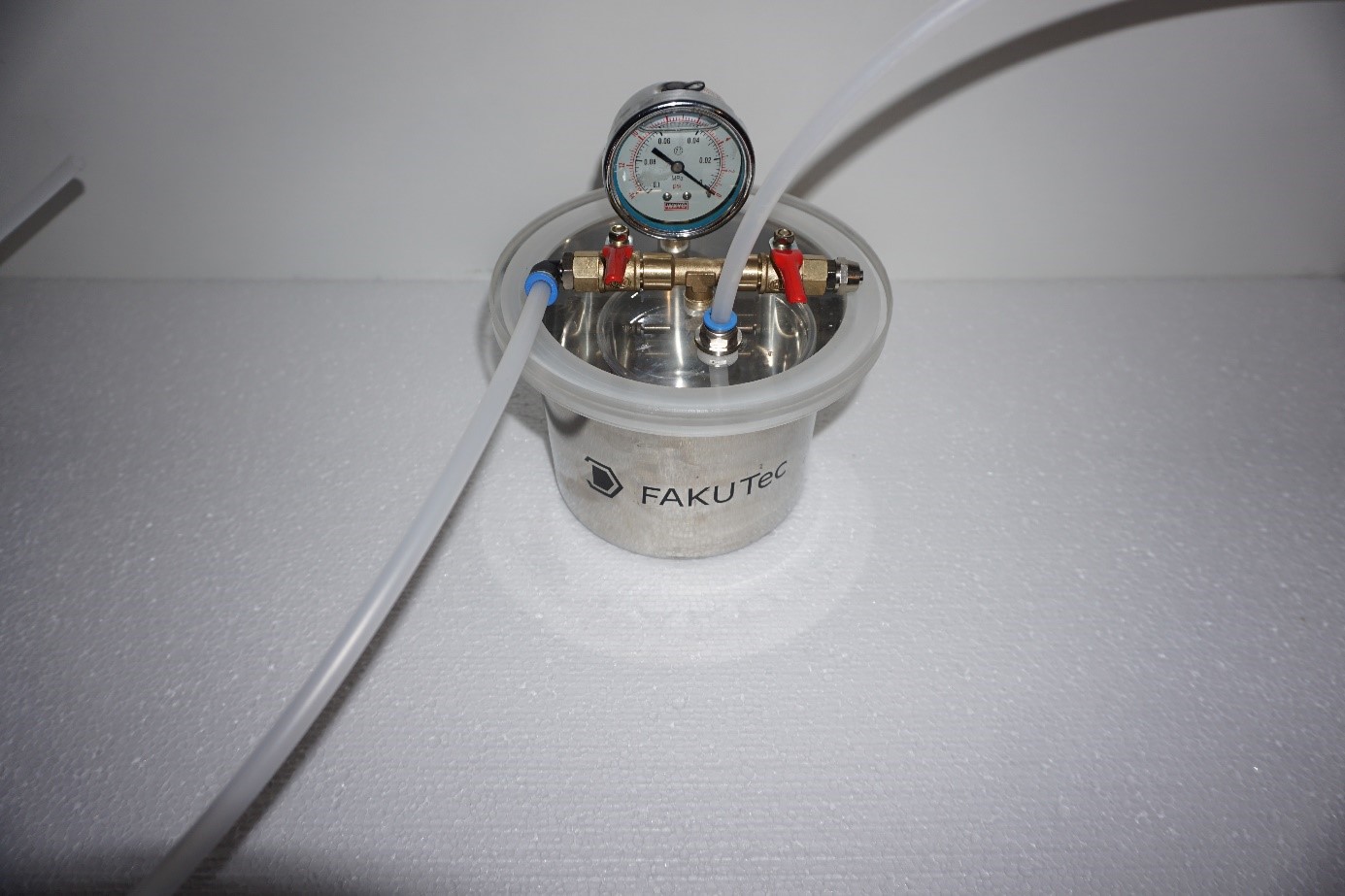

VAKUBox

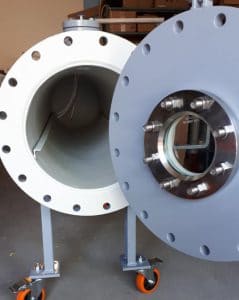

DRUCKBox

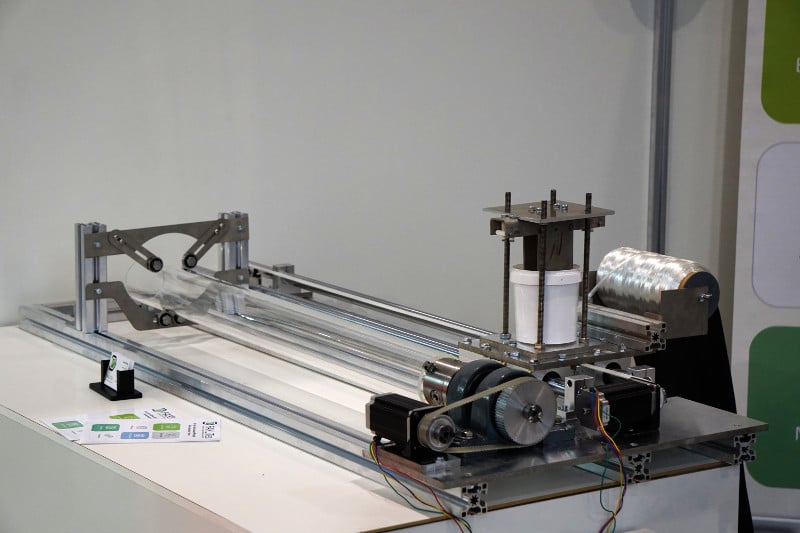

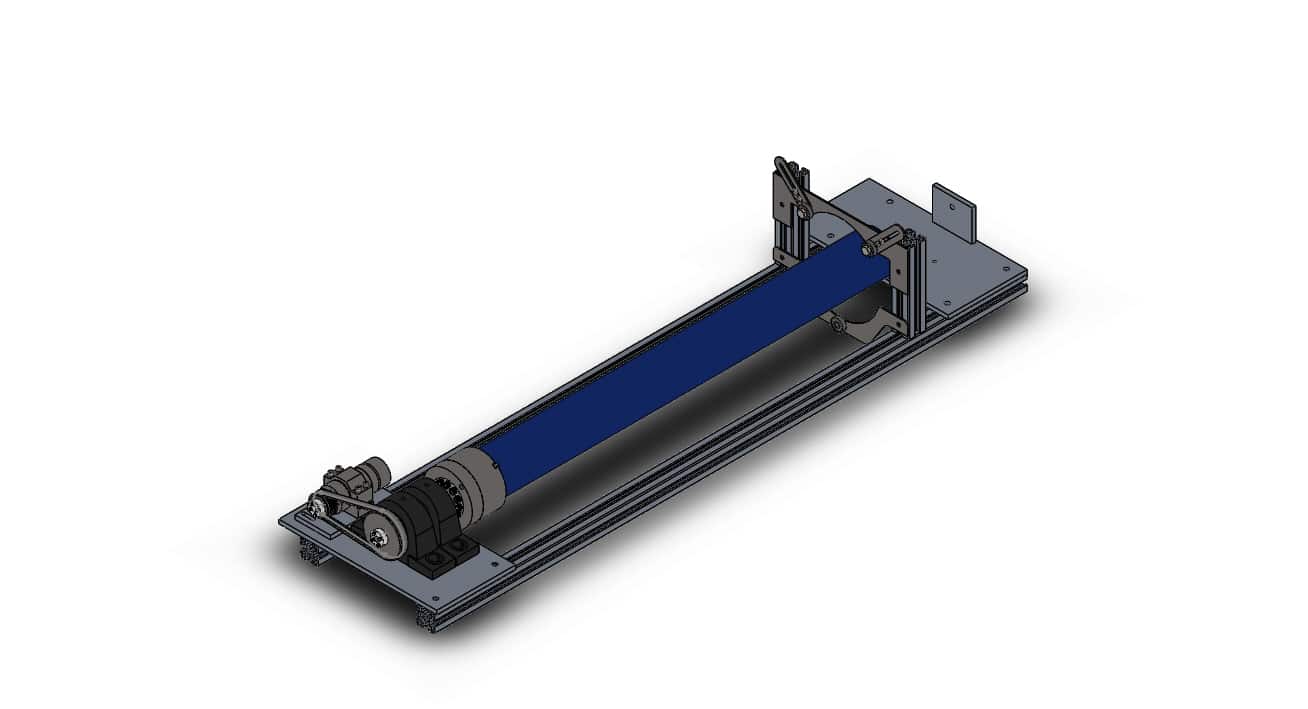

winding machine

slinger

FAQ

Frequently asked questions

What is the difference between the KLEBox and the RTMBox?

The RTMBox comes with a vacuum and positive pressure function. The KLEBox is constructed for a higher positive pressure and can be combined with a pneumatic remote.

When should I use the VAKUbox?

The VAKUBox is an inexpensive solution for working with negative pressure. It can be used as resin trap, for degassing and as a tool to influence the distribution of resin.

What do I need the HOTBox for?

Many components have to be tempered after manufacturing. We can configure an isolated chamber customized to your needs.

Which box offers a lightweight alternative for autoclaves?

The DRUCKBox provides a horizontal platform that can be used for positioning your hand-laminated component and for applying external pressure additional to vacuum bagging.

How many axes does my winding machine need for manufacturing a simple pipe?

You only need the basic model with 2 axes. Flexible programming enables you to manufacture even more complex layer structures with this basic variety.

Does the winding machine provide the ability to wind even rectangular or conical components?

The modular construction of the winding machine enables to spin even rectangular winding spindles. If you want to manufacture components with different diameters, we recommend using an additional infeed axis.

Which advantages do centrifugally cast pipes have?

Centrifugally cast pipes have a higher fibre volume ratio in the outer perimeter due to the different density of fibres and matrix. Through an individual dosage of resin you can apply a smooth protective surface on the inner side. Pipes that are manufactured that way are ideal for being used in pipeline constructions.